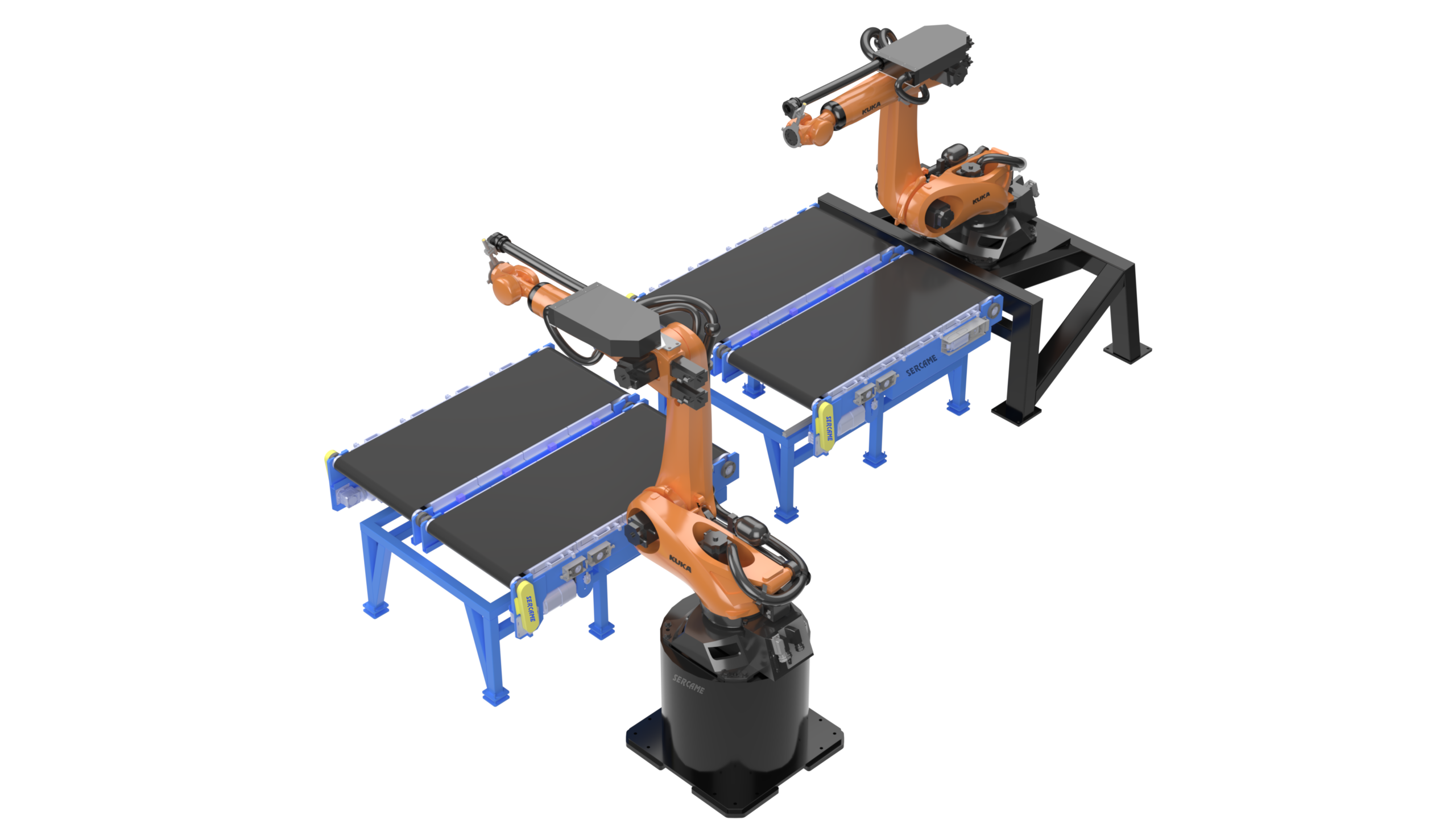

Belt

Continuous, single-level surface design for uniform, interruption-free transport.

Belt Drift Control System

System developed by Sercame to correct belt deviation and prevent side damage.

· ·

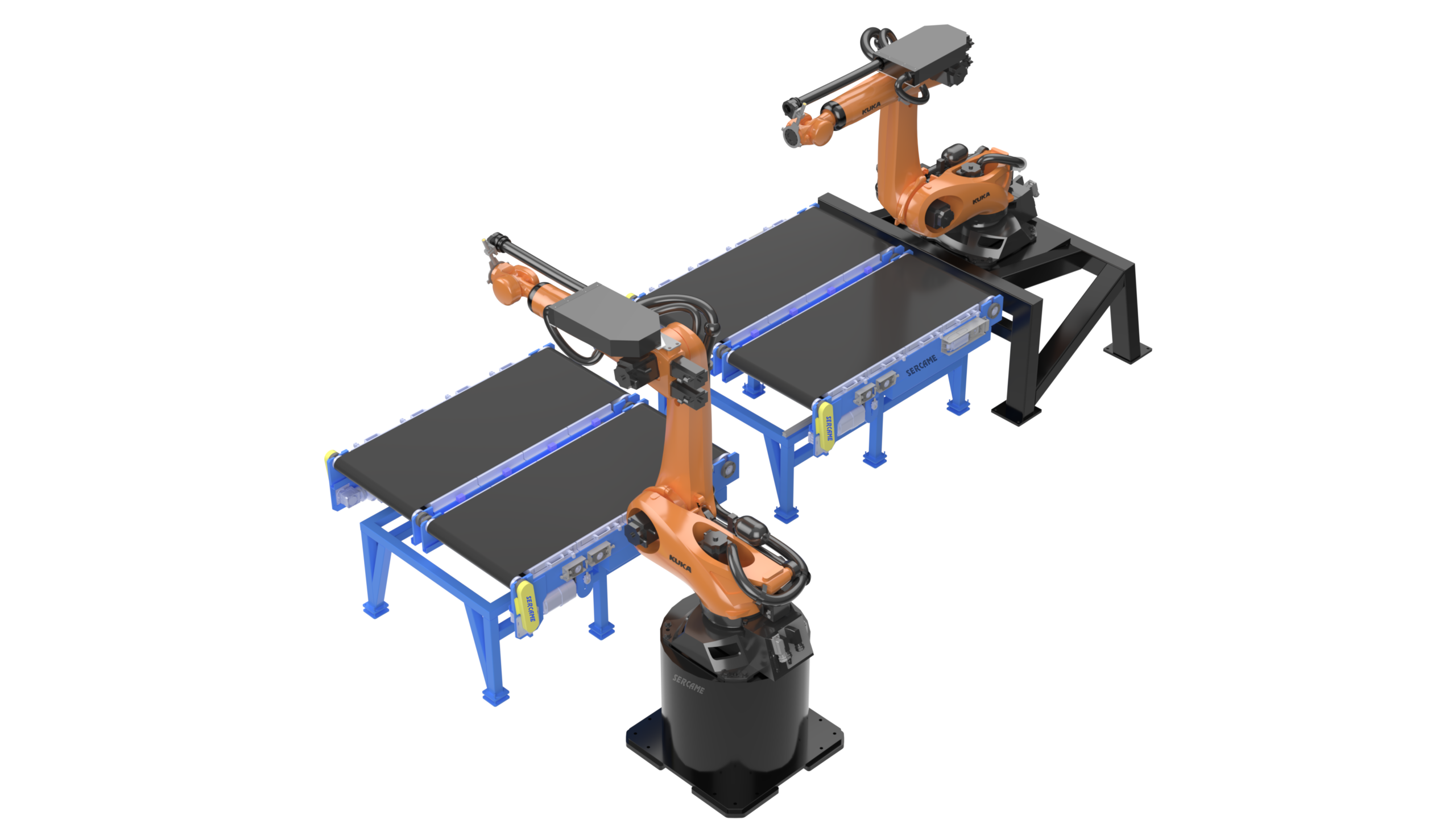

Continuous, single-level surface design for uniform, interruption-free transport.

System developed by Sercame to correct belt deviation and prevent side damage.

· ·

High-rigidity structure that maintains stability under heavy loads.

Dimensional control that ensures smooth, linear movement without deviation.

Provides a stable, precise installation with zero play.

· ·

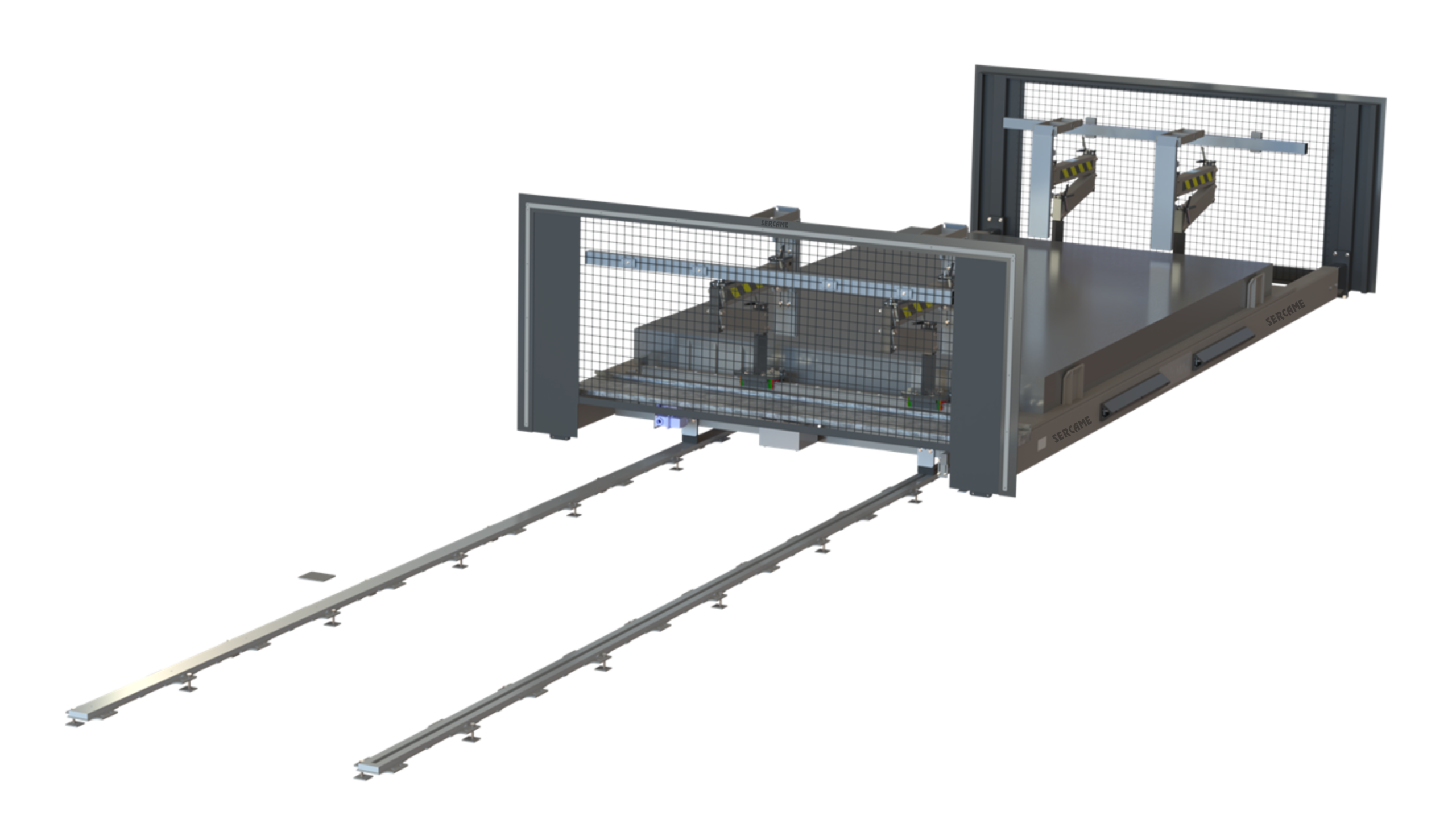

Compatible with pin pallets for blank positioning, adapting to processes with different references and formats.

Stops positioned to protect both the table and surrounding equipment

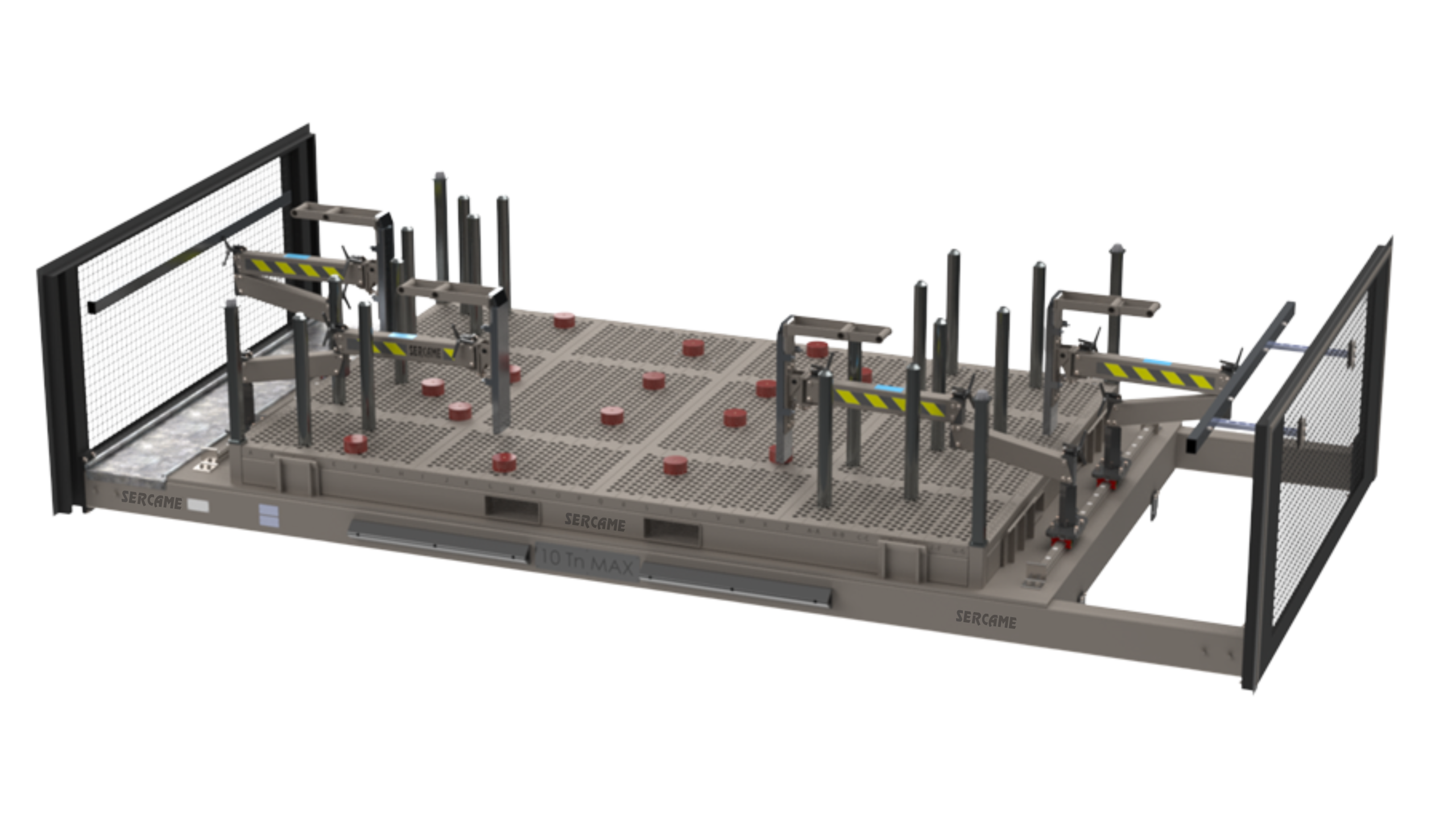

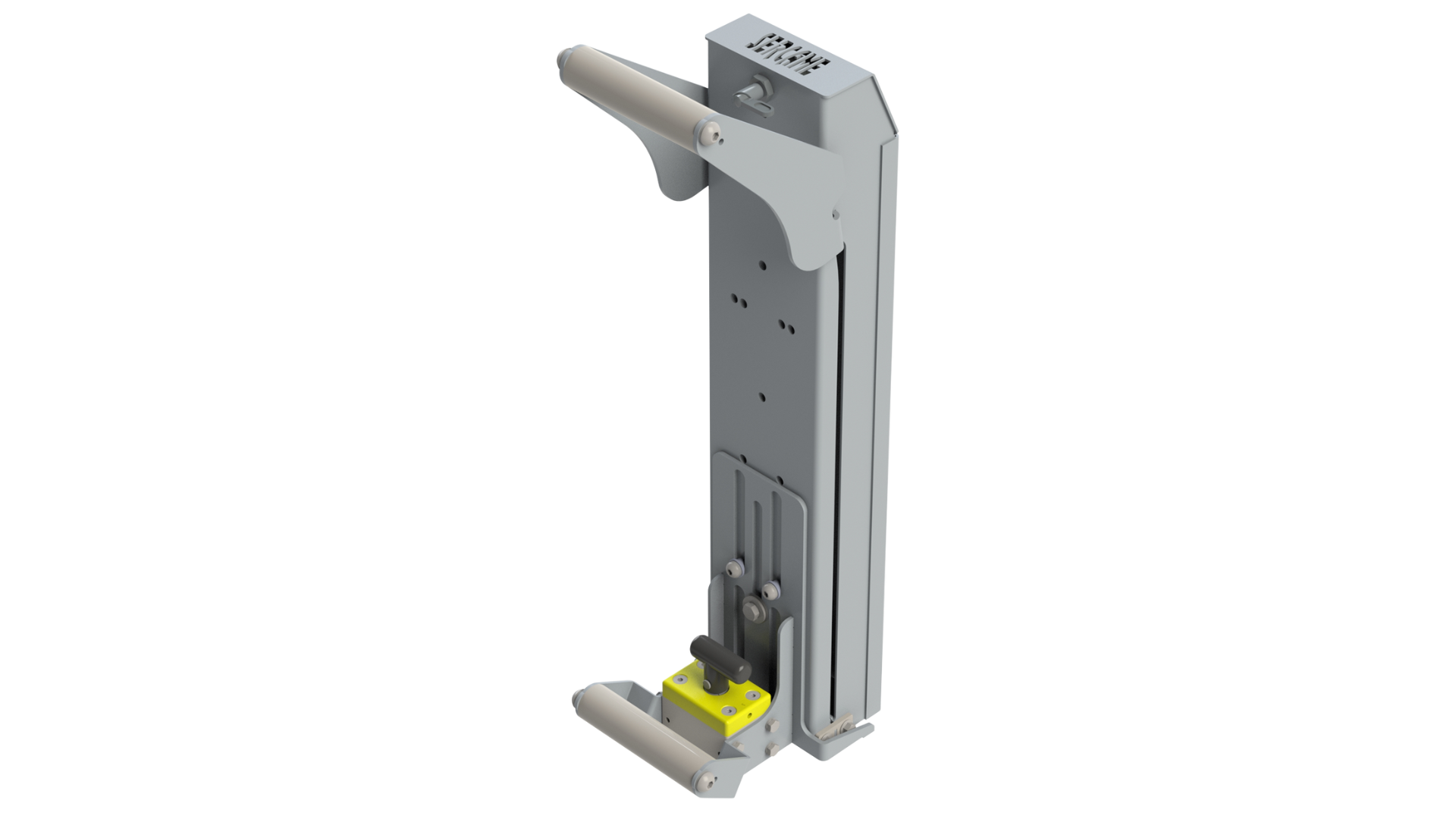

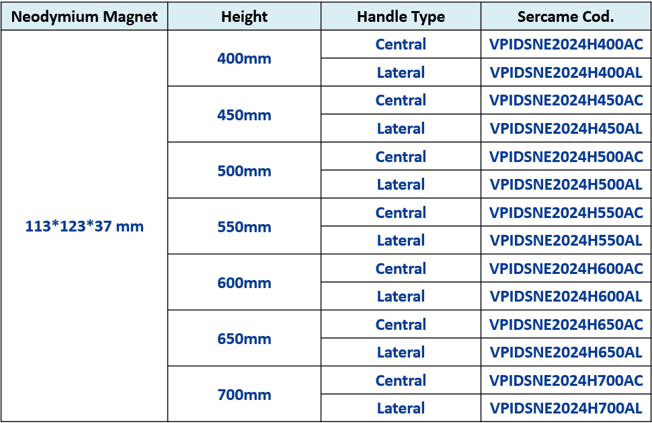

Height- and length-adjustable system that allows precise positioning of magnets or blowers over the blank stack, ensuring optimal reach and operational flexibility.

Structure that enables longitudinal movement of pantographs along the table, allowing fine adjustment according to format and application.

· ·

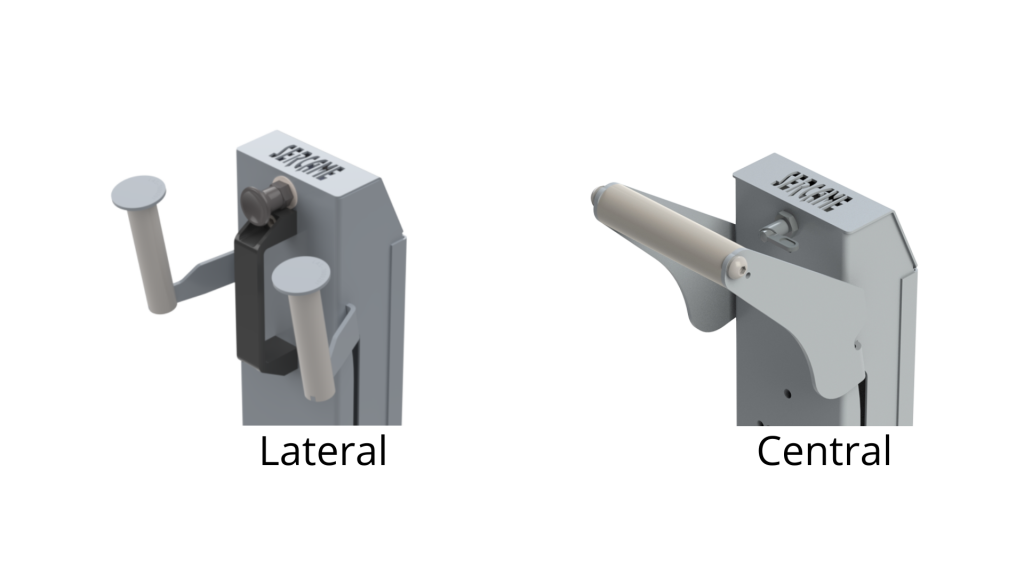

Prevents the movement of the magnet when it is not in operation, maintaining the safety of operation and transport.

High power for separation between formats.” or “High power for opening between formats.

Quick maintenance, without the need for special tools.

Flexibility for different package configurations.

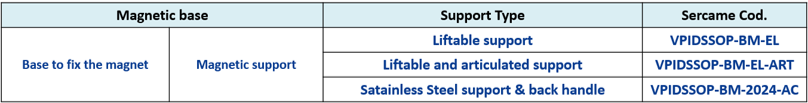

Secure and stable clamping on any metal surface.”

· ·

Allows adaptation to the optimal working level, ensuring a stable transition and correct positioning of the blanks.

Adjustable extension to bring the conveyor closer to the exact transfer point, preventing part drops or misalignment.

Independent lateral positioning of each belt to accommodate varied geometries and irregular formats.