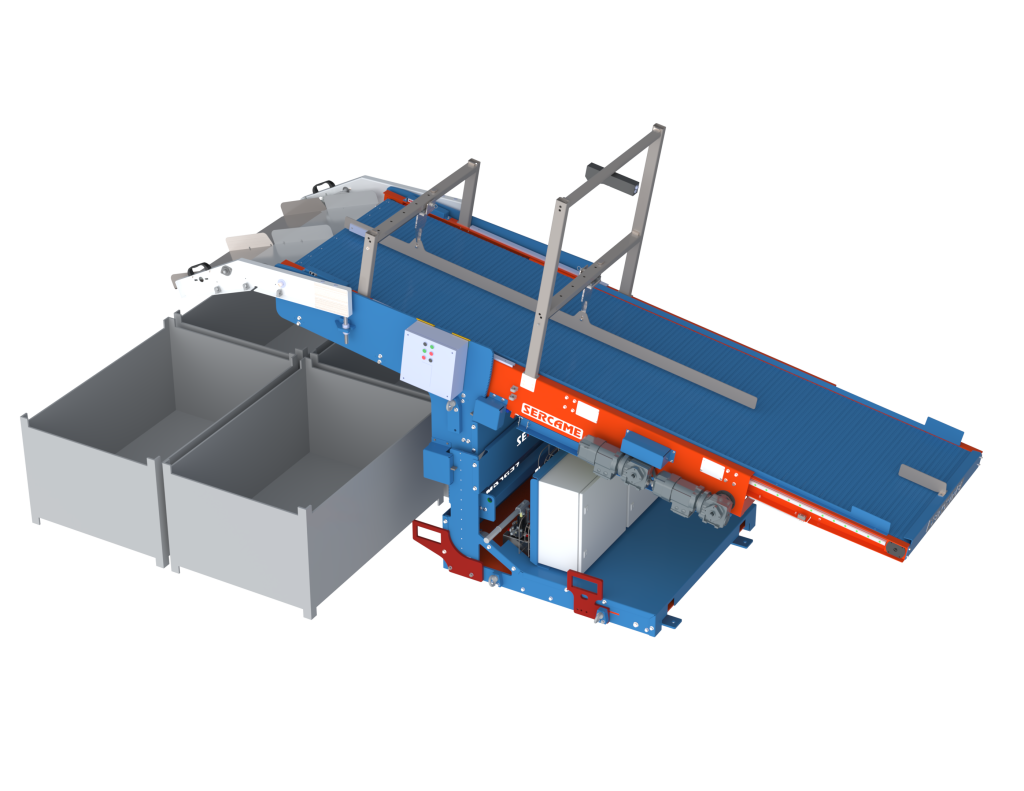

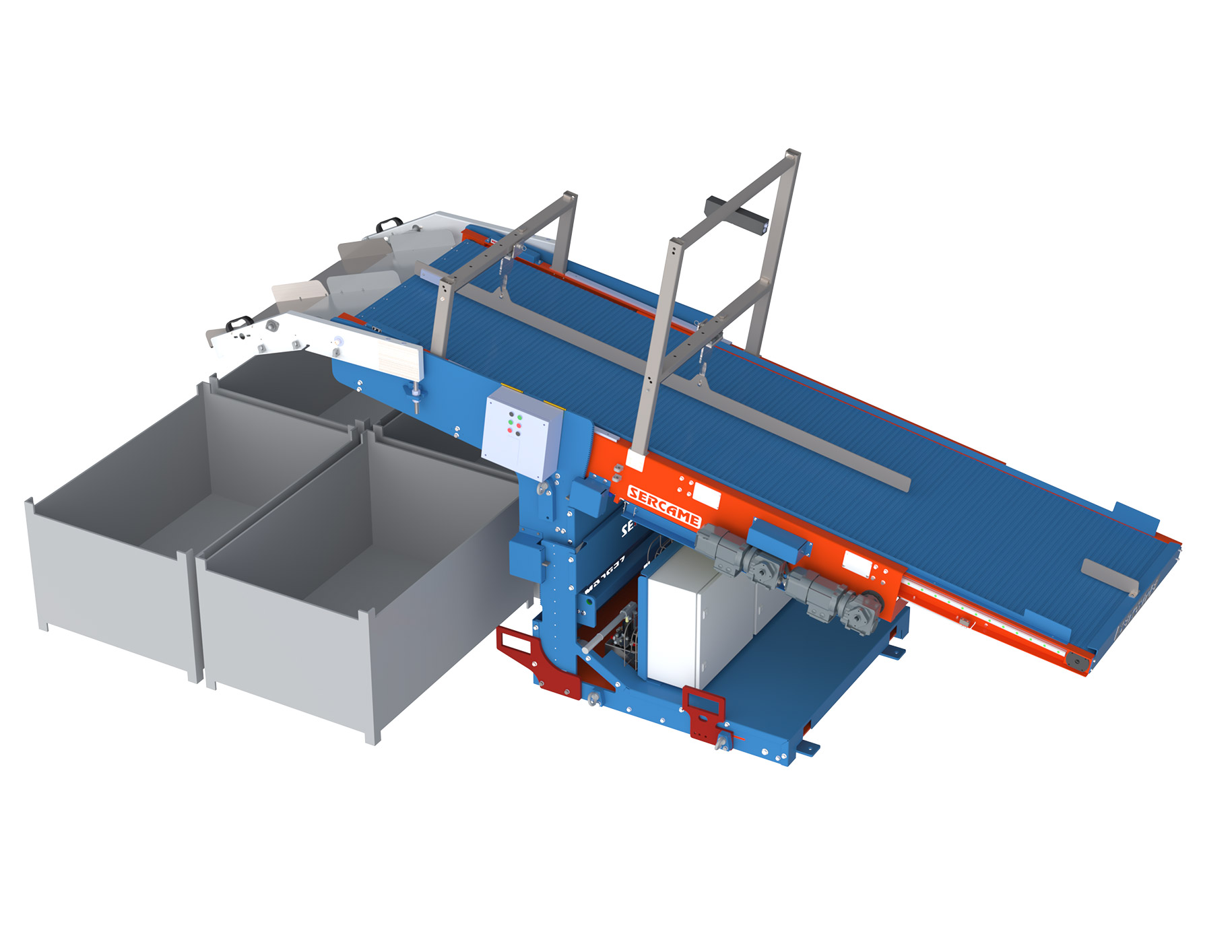

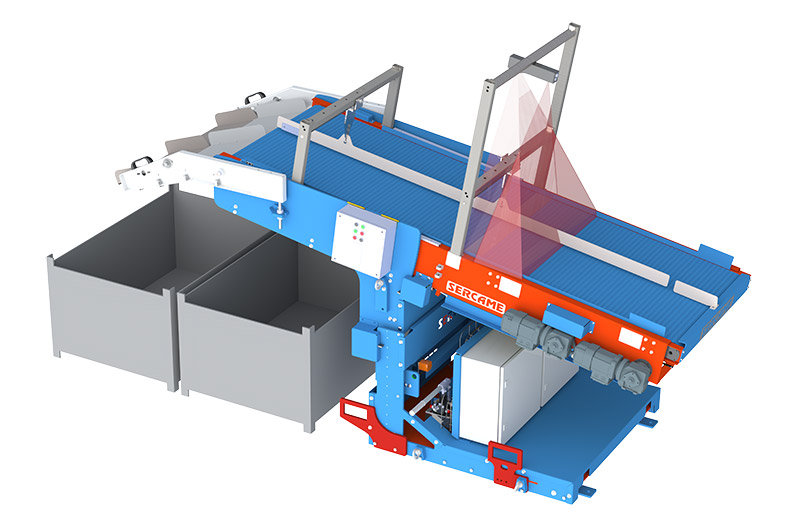

Automated container-change tray

Manages up to 4 containers without stopping production.

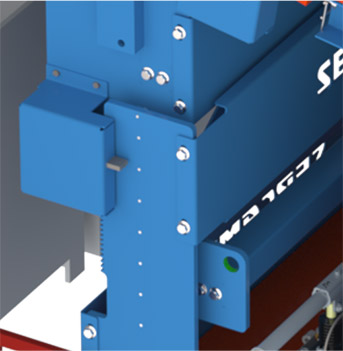

Integrated piece counter

Ensures accurate monitoring and complete traceability of production counts.

Vertical height adjustment

Allows positioning of the conveyor at the optimal working level within the line.

Independent inclination adjustment

Enables precise angle configuration according to the required flow.

Acetal (POM) modular belt

Easy module replacement. High-resistance thermoplastic, low coefficient of friction, and excellent dimensional stability.

Telescopic frame

Telescopic extension structure.

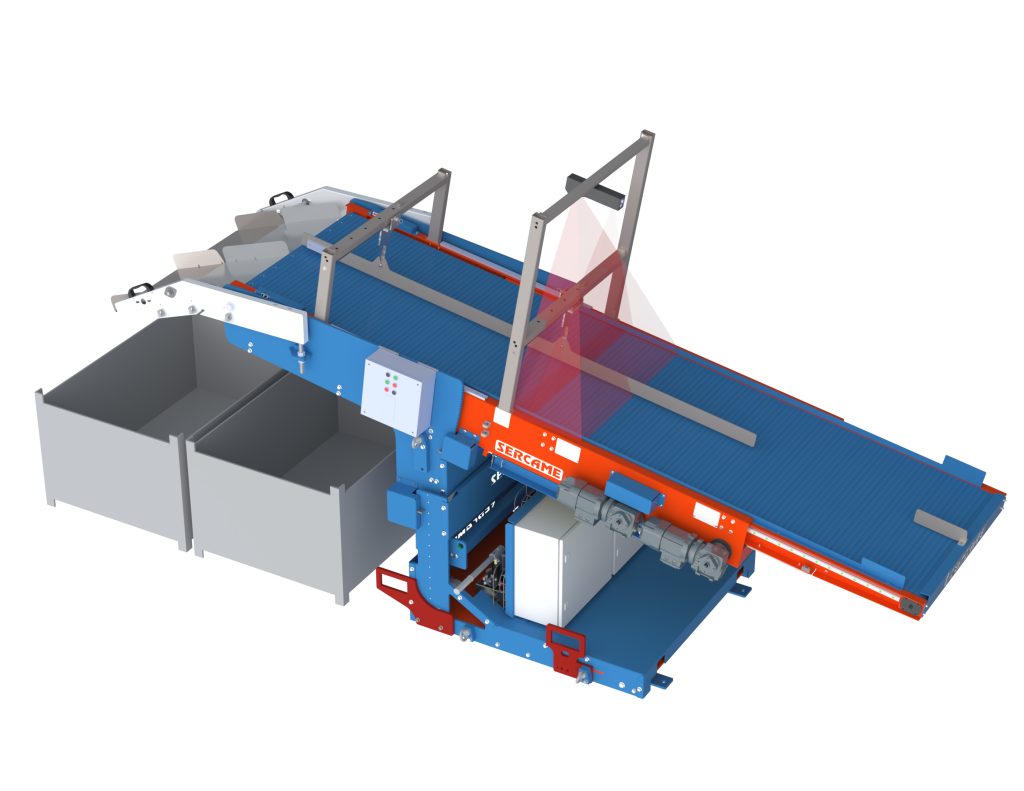

Vesatile conveyor + Quality control

Vision system for quality inspection

High-precision detection of defects or deviations, ensuring conformity before reaching the container.

Key Benefits

- Full versatility: Complete adjustment range for multiple operational scenarios.

- Optimized maintenance: Fast interventions with easy-to-replace components.

- Production efficiency: Automatic tray switching redirects the flow between containers without production stops.

- Operational reliability: Robust design with long-life industrial components.