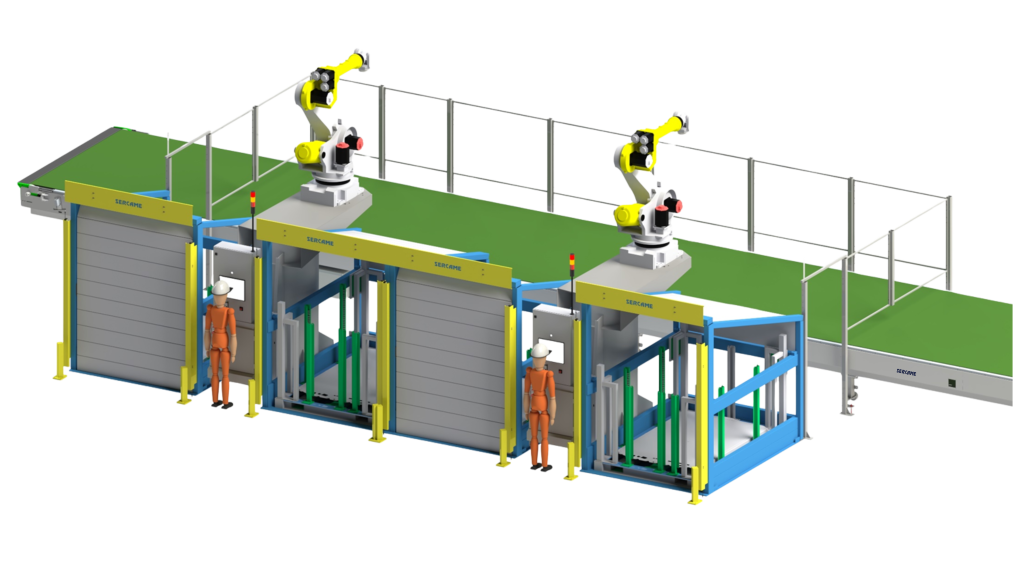

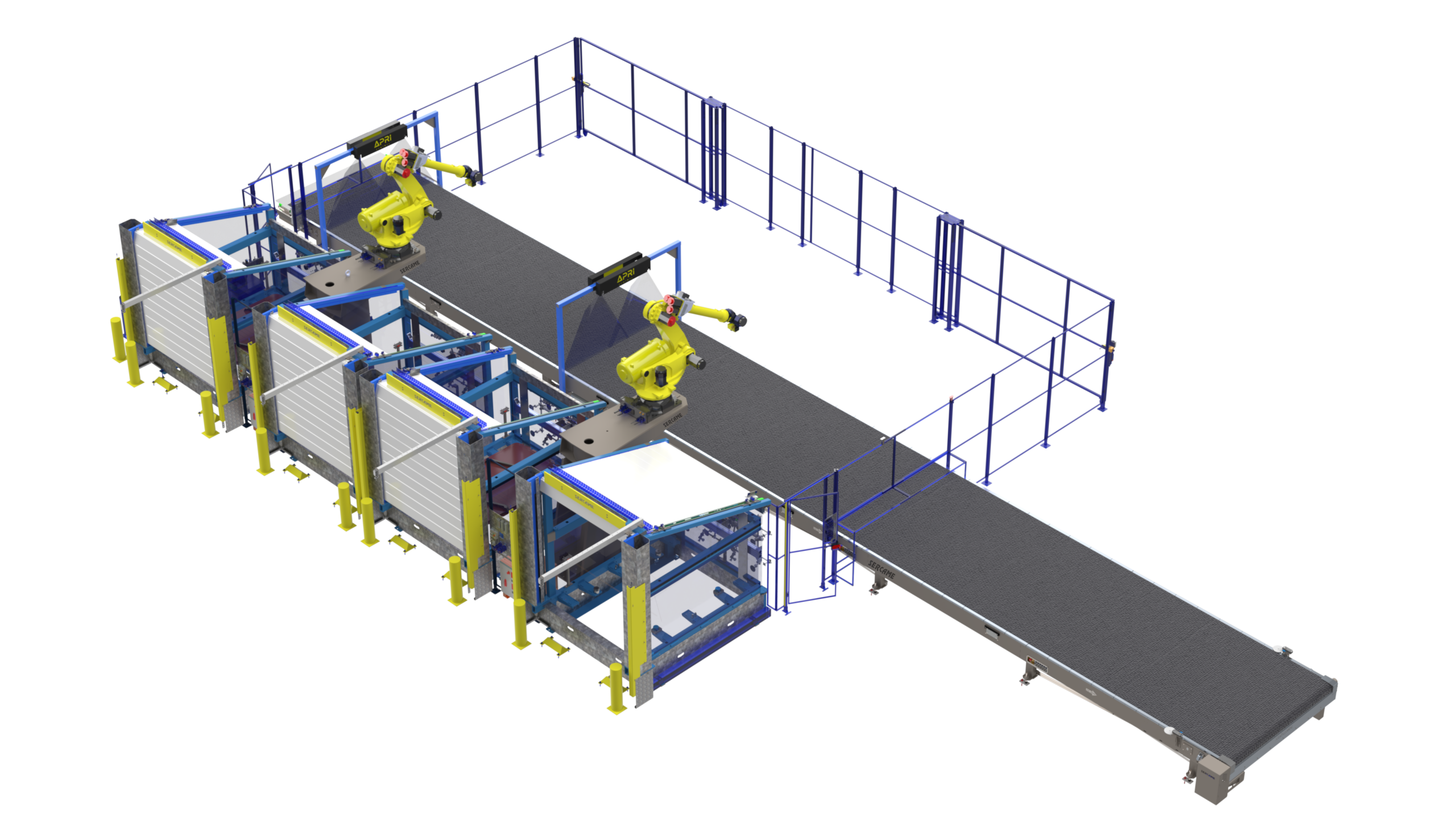

Autoracking cages

Protected loading zones equipped with reverse-action doors that coordinate robot–operator interaction, enabling continuous and safe operation.

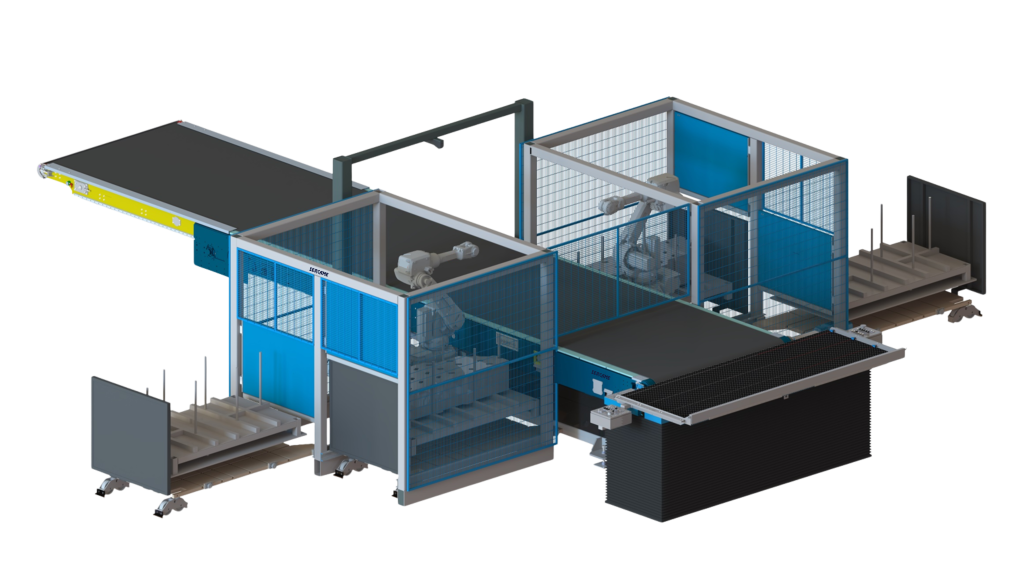

3D vision system

Dimensional inspection and verification of critical points, with the ability to automatically separate OK and NOK parts.

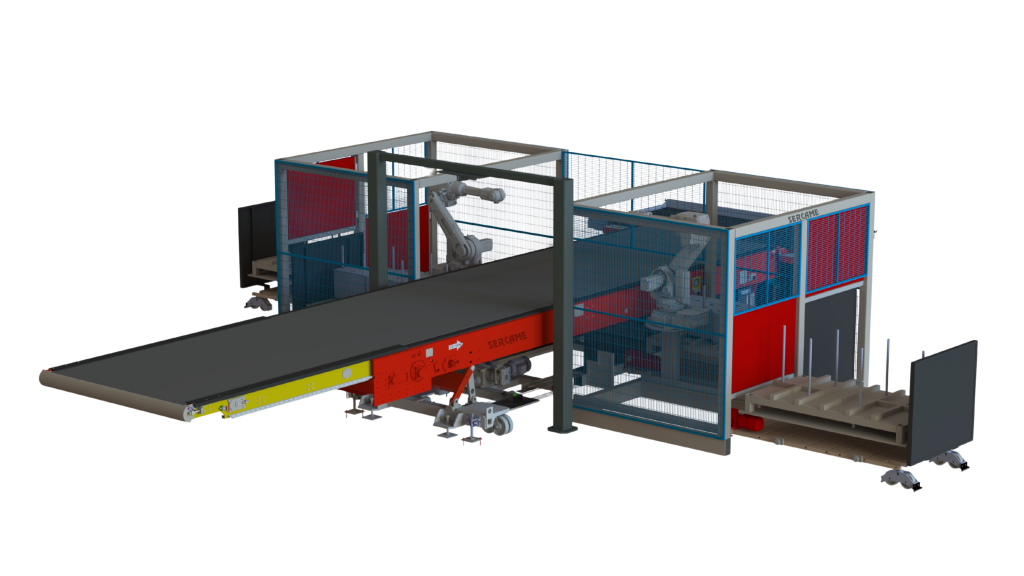

Handling robots

Responsible for accurate part placement inside containers, ensuring cycle consistency, repeatability, and process quality.

Conveyor

Transfers parts from the press to the racking area, maintaining orientation and guaranteeing stability throughout the entire path.

Key Benefits

- Full automation: Integrated management of part handling, quality inspection, and container loading.

- Higher throughput: Continuous flow with no stoppages for container changes.

- Operational safety: Physical separation between robot and operator zones.

- Real traceability: Automatic counting and classification of parts.

- Guaranteed repeatability: Stable and precise deposition on every cycle.

Aplications

- High-speed lines: Ideal for fast-cycle environments where automation prevents saturation and unnecessary stops.

- Parts with critical areas: Suitable for geometries that require controlled handling to avoid deformation or damage.

- Mixed environments: Perfect for operations where robots and operators share the workspace, with systems that ensure safe coexistence without compromising productivity.