The front-of-line systems we develop at SERCAME guarantee precise and continuous sheet metal feeding, preventing bottlenecks and maintaining process stability. Our equipment covers everything from destacking to final positioning toward the press, adapting to different formats, materials, and production rates. Each development is conceived to elevate the efficiency, safety, and reliability of the operation.

Blank separators

|

FOL

|

Magnetic

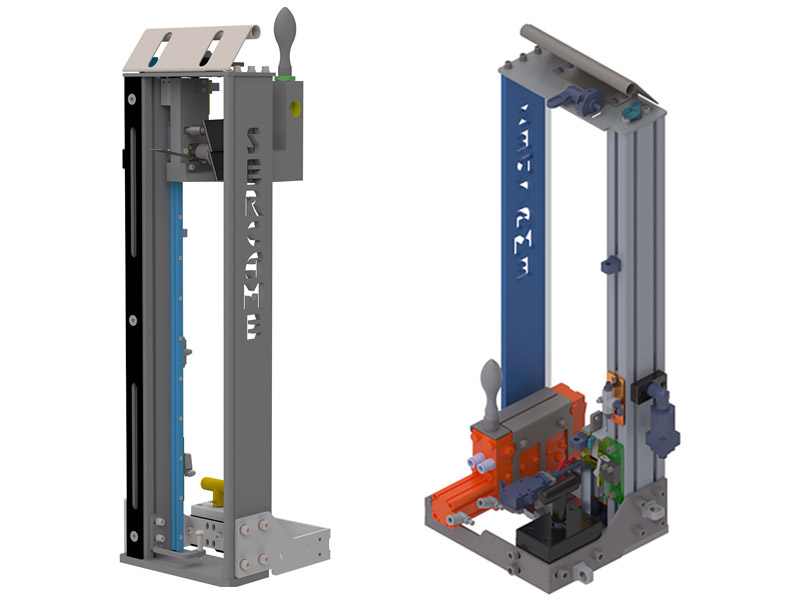

Self-descending magnet | Sercame

The Sercame's auto-descending magnet is designed to ensure efficient and reliable blank separation in ferrous sheet destacking processes. Its gravity-assisted mechanism automatically adjusts to the decreasing height of the stack, maintaining optimal contact and guaranteeing a consistent and stable separation throughout the cycle. A robust, low-maintenance solution ideal for high-productivity stamping environments.

Blank separators

|

FOL

|

Pneumatic

Destacking blower | Sercame

Sercame's destacking blower generates a precise separation between blanks using air flow, preventing the robot from picking up multiple sheets at once. The self-descending mechanism allows the head to adjust by gravity as the stack decreases, ensuring constant operation without manual intervention.

Blank separators

|

FOL

|

Magnetic

Retractable magnet | Sercame

Sercame’s retractable magnet is designed for blank destacking in systems equipped with self-adjusting tables. Its robust and precise structure allows controlled forward and backward movement of the magnet assembly, ensuring efficient and safe sheet handling throughout the process. It automatically adapts to the stack height, maintaining a continuous and reliable feeding flow into the line.

Blank separators

|

FOL

|

Magnetic

Electromagnet | Sercame

Sercame’s electromagnet is an alternative to permanent magnets for blank separation during the destacking process. Its controlled magnetic activation and deactivation allow for more flexible and precise handling when configuring the stack.

FOL

|

Infeed conveyors

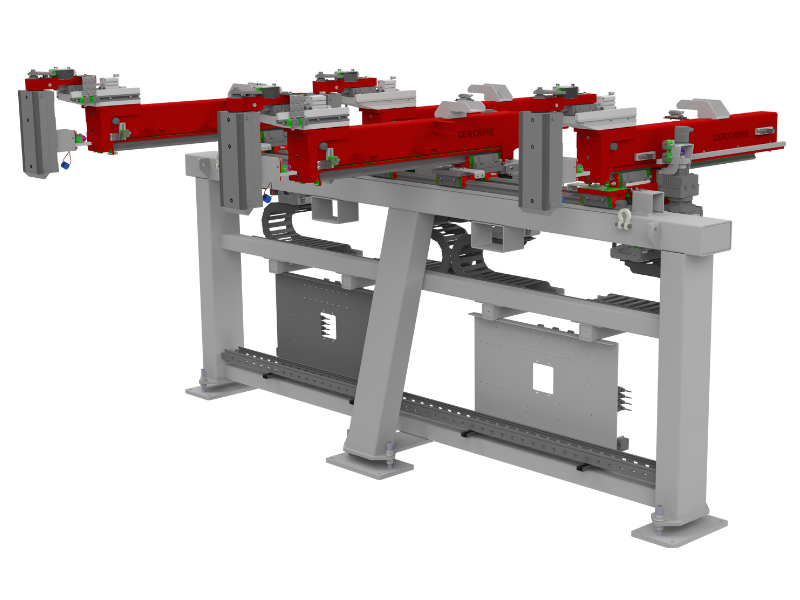

Infeed conveyor multitrack | Sercame

Sercame’s multitrack infeed conveyor ensures precise and stable feeding into the press. Its adjustable structure, featuring independently positioned belts and telescopic frames, adapts easily to different blank geometries, guaranteeing aligned and efficient transfer in any Front-of-Line configuration.

FOL

|

Infeed conveyors

Infeed conveyor | Sercame

The Sercame's infeed conveyor is designed to ensure stable and precise feeding into the press, guaranteeing that each blank arrives aligned and in the correct position. Its stable and continuous design enables smooth transfer, reducing misalignment and optimizing Front-of-Line cadence.

Destacking Auxiliaries

|

FOL

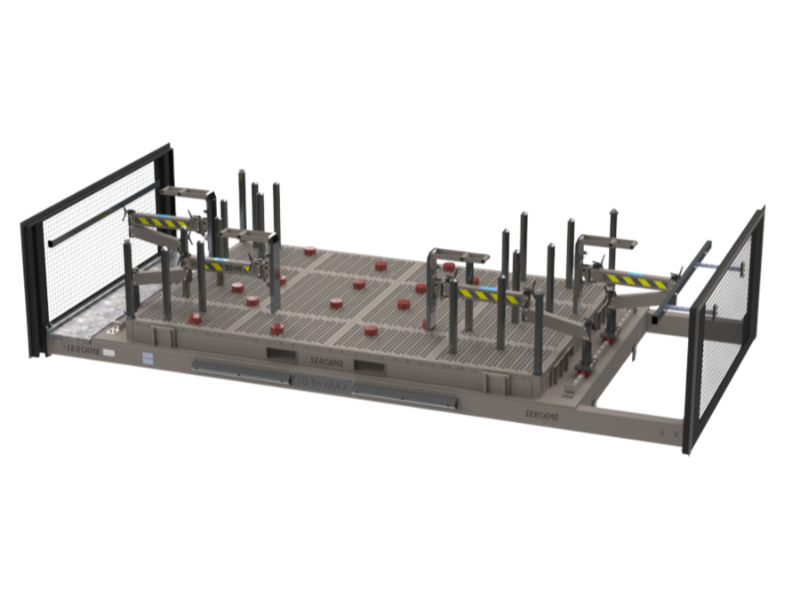

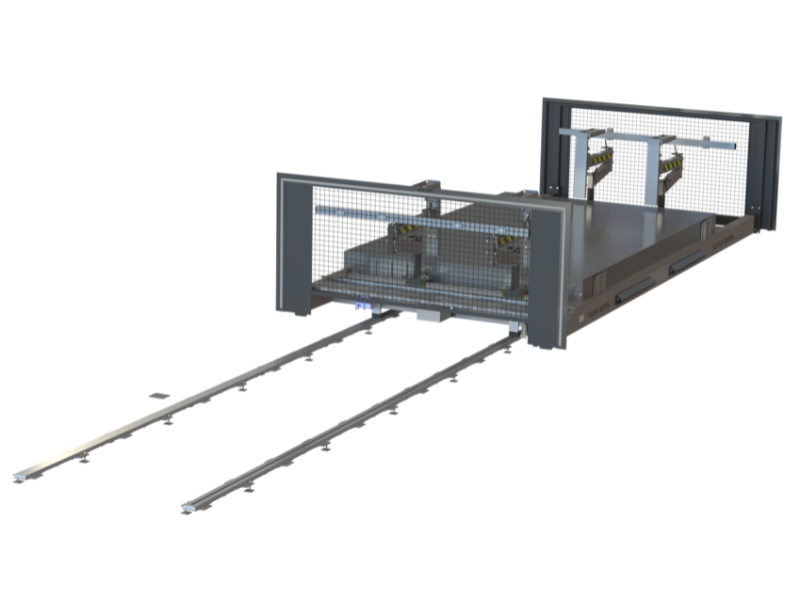

Destacking table | Sercame

Sercame’s destacking table provides a robust, stable platform for handling blank stacks. Its design allows both direct placement of blanks and the use of pin pallets, and it supports configurations with positioning systems for destacking equipment. Additionally, its rail-mounted movement facilitates operation in and out of the line, maintaining ergonomics and efficiency throughout the process.

Destacking Auxiliaries

|

FOL

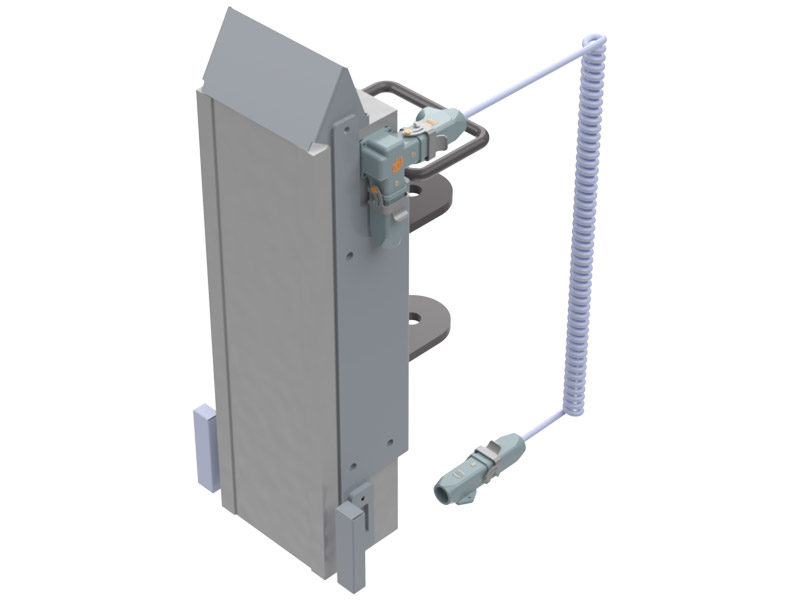

Rails | Sercame

Sercame’s industrial rails are designed to ensure safe, stable, and precise movement of loading tables. Their robust construction and controlled geometry reduce vibrations and optimize maneuverability. Engineered for demanding environments, they deliver reliability, long service life, and smooth mobility even under heavy loads.

Destacking Auxiliaries

|

FOL

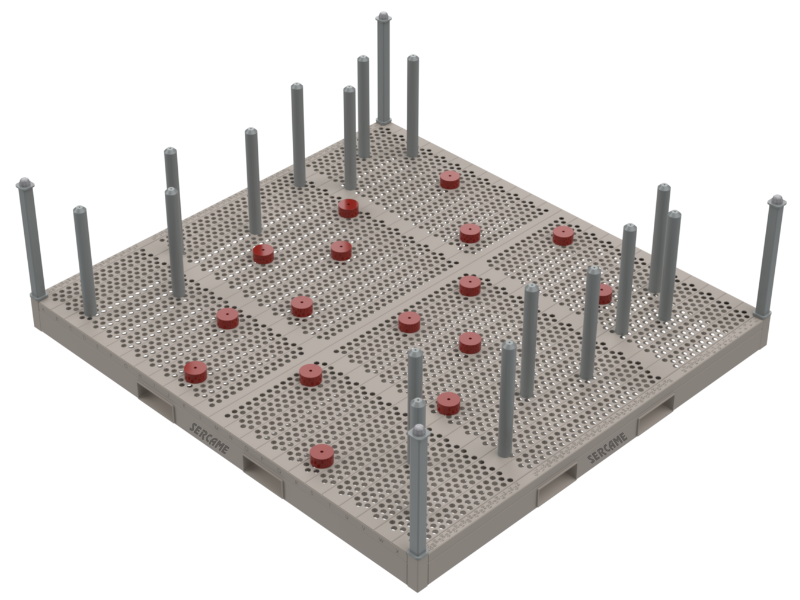

Pin pallet | Sercame

Sercame's Pin Pallet is a robust solution for the handling and positioning of blanks at the front of the line. Its metallic structure incorporates octagonal housings that allow the reference pins to be placed in multiple positions, guaranteeing flexibility in the orientation and alignment of parts according to production needs.