SERCAME’s complementary developments are designed to enhance the overall efficiency of the production line and strengthen its safety. These are specific solutions that support operations by optimizing time, improving internal logistics, and ensuring safe conditions for operators-contributing to a more agile, organized, and reliable production environment.

Complementary solutions

Grippers Storage | Sercame

The Sercame claw storage system integrates trays designed to organize and securely protect the transfer claws. Its vertical configuration optimizes floor space and facilitates operator access, combining order, safety, and ergonomics in a single system.

Complementary solutions

Extractor and Tongs for Ceramic Rollers | Sercame

Sercame's ceramic roller extractor, designed for Schwarts and Benteler hot-stamping furnaces, enables safe, fast, and ergonomic removal and replacement of ceramic rollers. Its operation is complemented by dedicated tongs that allow the secure handling of hot or damaged rollers, ensuring an even safer and more controlled maintenance process.

Complementary solutions

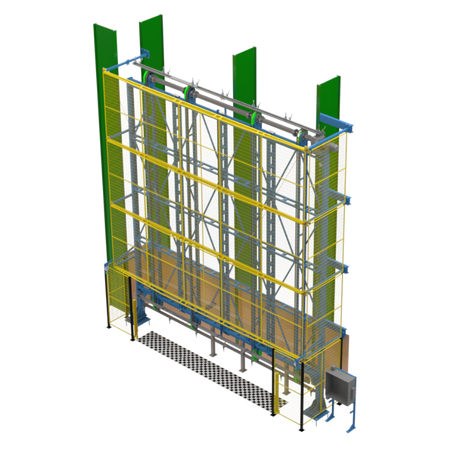

Transfer grippers simulator | Sercame

The Sercame transfer grippers simulator allows operators to prepare, adjust, and validate grippers configurations outside the press, eliminating downtime and enabling faster changeovers. Its structure reproduces the real working conditions of the transfer system, allowing the die to be mounted, the grippers bars to be adjusted, and all movements or potential interferences to be verified before installation in the press. A robust, precise solution designed to maximize line availability.

Complementary solutions

Robot Platforms| Sercame

Sercame’s robot bases provide a rigid and precise structural platform designed for the demanding environments of stamping lines. Engineered to ensure dimensional stability and vibration absorption, they deliver the reliability required for accurate and consistent handling operations.

Complementary solutions

Press safety block | Sercame

Sercame’s press safety block is a mechanical safety element designed to prevent accidental press closure during maintenance or any intervention inside the machine. Its solid structure, mounted on an adjustable pantograph, ensures reliable and stable protection, providing operators with an essential physical barrier in any stamping environment.